How Cabentry makes Shamrock Cabinets more productive

-

Brent Atkins

- November 15, 2021

Company Snapshot

Shamrock Cabinets

Jasper, IN

1962

40

Overview

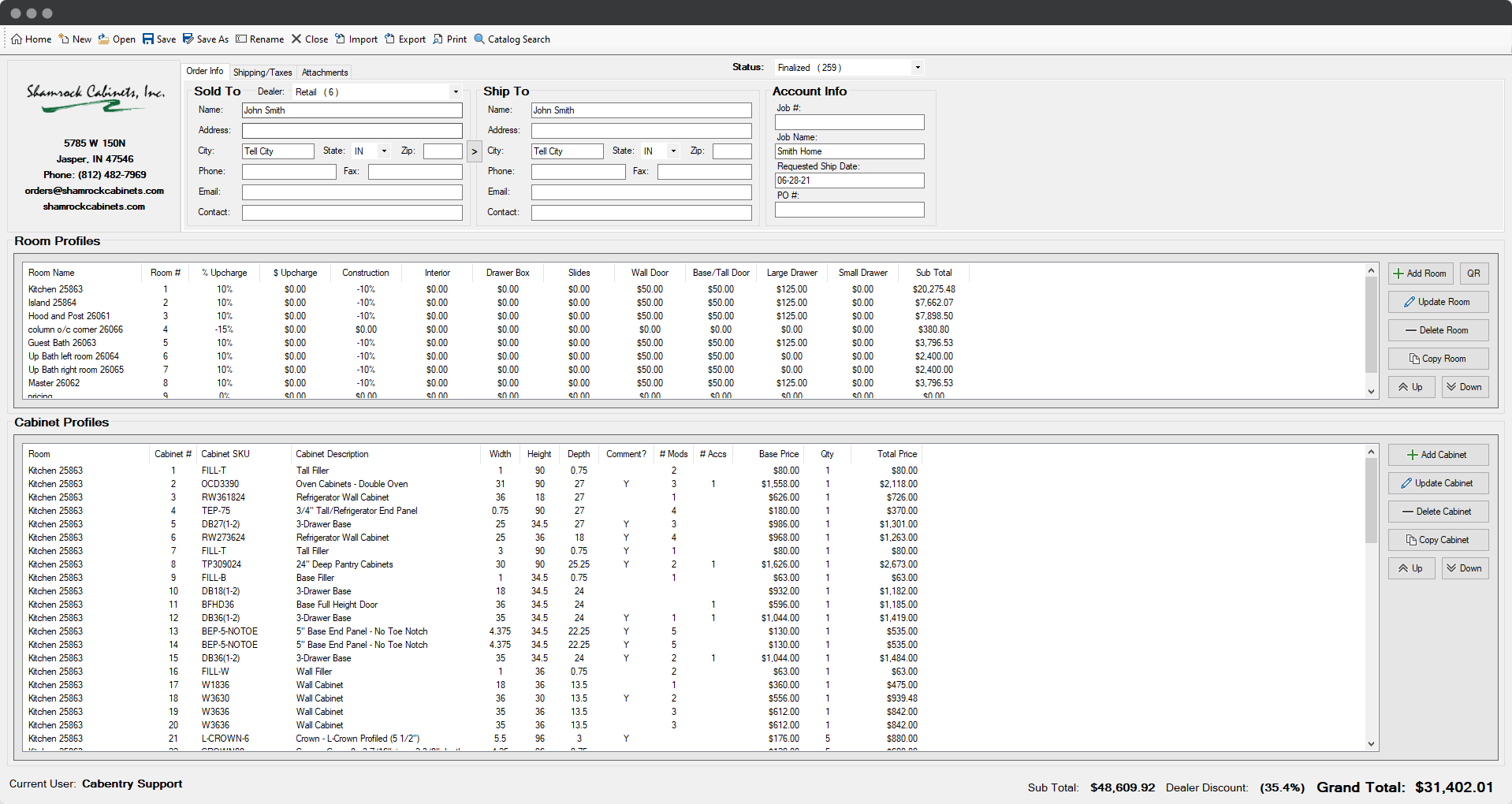

Shamrock Cabinets in Jasper, IN have been building custom kitchen and bath cabinetry for nearly 60 years but in the past few years they discovered their order confirmation process was a major bottleneck. After purchasing new equipment and improving their manufacturing processes, their engineering and order processing departments could not get enough orders out to the shop. Cabentry has given Shamrock a tool to help them solve their bottleneck challenges and better manage the entire order process.

The Challenge

In 2018, Shamrock Cabinets made substantial changes, they purchased new equipment and changed their manufacturing processes dramatically. This led to major improvements in production time. however, this created a problem in the office as they could no longer get jobs to the shop floor quick enough. Production was always nipping at the heels of the engineering department.

Shamrock discovered they could only process so many orders per day due the length of time it took to confirm each order. One of the issues that contributed to this bottleneck was the large variance in how incoming orders were formatted. Some orders were handwritten and others wrote them up in documents or spreadsheets, however due to the nature of custom cabinetry and the wide variety of vocabulary that differs from region to region, there were many misinterpretations and oversights.

Another contributing factor was the engineers had to build each order from scratch in Cabinet Vision, their manufacturing software. This made it exceedingly difficult for the engineers to be able to provide enough orders for production.

The Solution

After recognizing their ordering process was a bottleneck, Shamrock started looking for solutions. Shamrock decided to partner with Cabentry because of the Cabinet Vision integration and the ability to better control how and what their dealers order. The decision was made easier due to the relationship and trust that had been established over the years of working with Jasper Industrial Supply (a sister company to Cabentry).

After signing on, the catalog implementation began. Jay noted “It was challenging at first and we could have made better decisions on how we went about implementing our catalog into Cabentry. But it has been worth the struggle considering where we stand today with it.”

The Outcome

Cabentry has solved a variety of challenges for Shamrock that has led to them becoming more productive and profitable. Cabentry has improved the ordering process by providing a consistent order format to avoid confusion and saving time for the office staff by allowing dealers to quote themselves. Jay, an engineer at Shamrock said “Migrating to Cabentry has been a blessing. We have been able to take on more dealers and increase throughput. The time it took us to process a standard kitchen has been cut in half.”

The Cabinet Vision integration has also been a huge part of the time savings as the engineering department no longer has to start from scratch on each order.

Shamrock still has a few challenges to overcome but they feel confident to partner with the Cabentry team and look forward to working together to solve these challenges as new tools and features are released in the coming months and years.

Migrating to Cabentry has been a blessing. We have been able to take on more dealers and increase throughput. The time it took us to process a standard kitchen has been cut in half

Jay Braunecker | Project Engineer